Last Updated on 12/24/2025 by dtent.net

Why Learning How to Waterproof a Tent Matters

Knowing how to waterproof a tent is one of the most important skills for campers, outdoor enthusiasts, event organizers, and professionals who rely on tents for long-term or repeated use. Even high-quality tents can lose their waterproof performance over time due to UV exposure, abrasion, moisture, and improper storage.

Whether you are camping in the mountains, hosting an outdoor event, or using a tent for commercial purposes, understanding how to waterproof a tent correctly can prevent leaks, extend the lifespan of your tent, and significantly improve comfort and safety.

As a professional custom tent manufacturer with more than 10 years of production experience and a 6,000㎡ factory, Dtent has extensive knowledge of tent materials, coatings, seams, and waterproof technologies. This guide combines practical user-level advice with manufacturer-level expertise to explain how to waterproof a tent properly and effectively.

What Does “Waterproofing a Tent” Actually Mean?

Before learning how to waterproof a tent, it is important to understand what waterproofing involves.

Waterproofing a tent means creating or restoring a protective barrier that prevents water from penetrating the tent fabric, seams, and floor. This protection is usually achieved through:

Waterproof coatings (PU, silicone, PVC)

Durable Water Repellent (DWR) treatments

Seam sealing

Proper tent design and construction

From a manufacturer’s perspective, waterproofing is not a single step—it is a system.

How Tents Lose Their Waterproof Performance Over Time

Even factory-new tents can gradually lose waterproofing. Common reasons include:

UV damage breaking down coatings

Repeated folding and abrasion

Dirt and oils clogging fabric pores

Improper cleaning methods

Long-term moisture exposure

Understanding these causes helps users apply the right waterproofing methods at the right time.

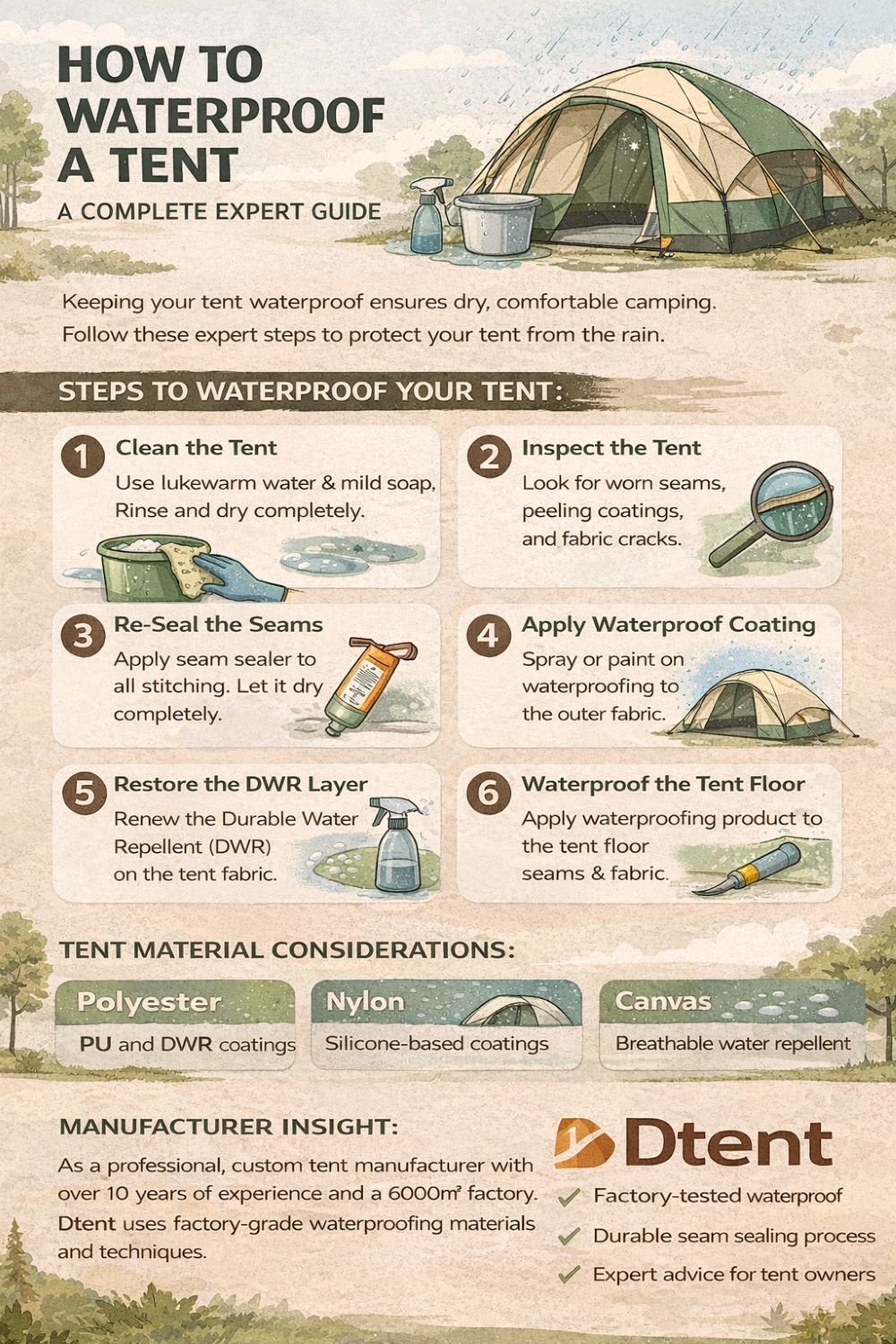

How to Waterproof a Tent: Step-by-Step Expert Guide

Step 1: Clean the Tent Thoroughly Before Waterproofing

Cleaning is the most overlooked step when learning how to waterproof a tent.

Why this matters:

Waterproofing products cannot bond properly to dirty or oily fabric.

How to do it correctly:

Set up the tent or lay it flat

Use lukewarm water

Use a soft sponge or cloth

Apply mild soap (never harsh detergents)

Rinse thoroughly and let the tent dry completely

From a manufacturer’s perspective, improper cleaning is one of the main reasons waterproofing treatments fail.

Step 2: Inspect the Tent Fabric, Seams, and Floor

Before applying any waterproofing product, carefully inspect:

Roof panels

Side walls

Seams and stitching

Tent floor and corners

Look for:

Peeling coatings

Cracks in seam tape

Thin or worn fabric areas

This inspection helps you decide where and how to waterproof a tent effectively.

Step 3: Re-Seal the Tent Seams (Critical Step)

Seams are the most common leak points in any tent.

How to waterproof a tent seam properly:

Use a seam sealer compatible with your tent fabric

Apply sealer evenly along stitched seams

Focus on roof seams and corners

Allow full curing time (usually 12–24 hours)

Professional tent manufacturers like Dtent apply seam sealing during production, but resealing is often required after long-term use.

Step 4: Apply a Waterproof Coating to the Tent Fabric

This is the core step when learning how to waterproof a tent.

Common waterproofing coatings include:

PU (polyurethane) coatings

Silicone-based waterproofing sprays

Acrylic-based treatments

Application tips:

Choose a product designed for tents

Apply in a well-ventilated area

Use even strokes with a spray or sponge

Avoid over-saturation

Let dry fully before packing

From a factory perspective, correct coating thickness is essential—too little fails, too much cracks.

Step 5: Restore the Durable Water Repellent (DWR) Layer

DWR helps water bead and roll off the tent surface instead of soaking in.

Signs your DWR needs renewal:

Water no longer beads on fabric

Fabric darkens when wet

How to waterproof a tent using DWR:

Clean the tent first

Apply a DWR spray evenly

Heat-activate if recommended (sun or low-heat dryer, if safe)

DWR does not make fabric waterproof alone—it works together with inner coatings.

Step 6: Waterproof the Tent Floor

The tent floor experiences the most wear and pressure.

How to waterproof a tent floor:

Clean and dry the floor

Apply a thicker PU-based waterproofing product

Focus on corners and high-pressure areas

Allow extended curing time

Manufacturers often use heavier coatings on floors for this reason.

How to Waterproof a Tent Based on Tent Material

Different tent fabrics require different waterproofing approaches.

Polyester Tents

Common in camping and event tents

Compatible with PU and DWR coatings

Easy to maintain

Nylon Tents

Lightweight but sensitive to UV

Often silicone-coated

Requires silicone-based waterproofing products

Canvas Tents

Naturally water-resistant

Requires breathable waterproof treatments

Needs regular maintenance

As a custom tent manufacturer, Dtent selects waterproofing systems based on fabric type and intended use.

How Often Should You Waterproof a Tent?

A common question is how frequently waterproofing should be done.

General guidelines:

Casual camping: once per season

Heavy use: every 3–6 months

Commercial or event tents: regular inspection after each project

From a factory standpoint, preventive maintenance is always more effective than emergency repair.

Common Mistakes When Learning How to Waterproof a Tent

Avoid these frequent errors:

Waterproofing a dirty tent

Using the wrong product for the fabric

Ignoring seam sealing

Packing the tent before curing

Overusing harsh detergents

These mistakes can reduce waterproof performance and damage fabric permanently.

Manufacturer Insight: How Waterproofing Is Done at the Factory Level

At professional tent factories like Dtent, waterproofing is integrated into production:

Fabric is pre-coated at material suppliers

Seams are heat-sealed or taped

Floors receive multi-layer coatings

Waterproof ratings are tested (e.g., hydrostatic head)

Understanding factory-level waterproofing helps users maintain tents properly in real-world use.

How to Test if Your Tent Is Properly Waterproofed

After applying waterproofing, testing is essential.

Simple testing methods:

Spray water over the tent surface

Check seams and corners for leaks

Observe water beading behavior

Inspect interior after drying

Testing confirms whether your waterproofing process was successful.

How Proper Waterproofing Extends Tent Lifespan

Correct waterproofing:

Prevents mold and mildew

Reduces fabric degradation

Maintains structural integrity

Improves resale or reuse value

From a manufacturer’s experience, well-maintained tents can last years longer than neglected ones.

Dtent’s Professional Perspective on Tent Waterproofing

With over 10 years of custom tent manufacturing experience and a 6,000㎡ production facility, Dtent emphasizes that waterproofing is not just a maintenance task—it is a system combining design, materials, coatings, and user care.

While factory waterproofing provides the foundation, correct user maintenance ensures long-term performance.

Frequently Asked Questions: How to Waterproof a Tent

Can any tent be waterproofed?

Most tents can be improved, but severely damaged fabrics may need replacement.

Is waterproofing permanent?

No. All waterproof treatments degrade over time.

Does waterproofing affect breathability?

Improper products can reduce breathability. Use tent-specific treatments.

Can I waterproof a tent at home?

Yes, with proper products and preparation.

How to Waterproof a Tent the Right Way

Learning how to waterproof a tent is essential for anyone who relies on tents for camping, events, or professional use. Proper cleaning, seam sealing, coating application, and regular inspection form the foundation of effective waterproofing.

From a manufacturer’s perspective, waterproofing is a partnership between factory engineering and user maintenance. With the right knowledge and methods, a tent can remain dry, durable, and reliable for many years.

As a professional custom tent manufacturer with more than 10 years of experience, Dtent encourages users to treat waterproofing as an ongoing process—not a one-time fix.

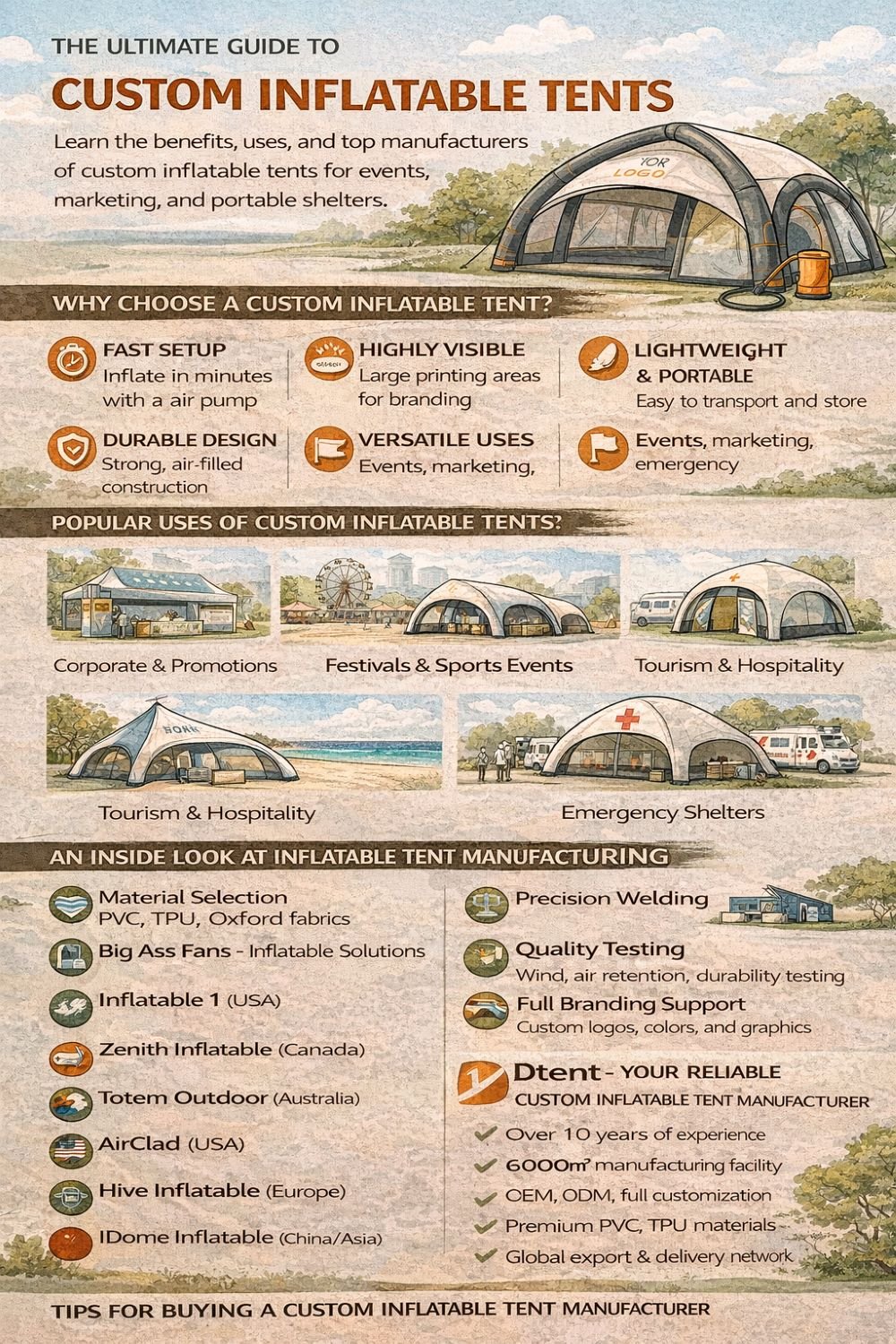

Are you a Trading Company or Manufacturer?

We are a manufacturer specialized in Folding tents, Outdoor umbrellas, Beach flags, Advertising Banners

Can you do design for my ideas or drawing?

Yes, we have experienced designers and our own molding factory. According to your requirements, we can design or open mold which has a competitive price.

How long does sample take?

Sample will be ready within 5-7 days, depends on your printing and material requirements.

What is your advantage?

Cost effective; with low price; Time effective: we promise to make the mass delivery within 30 days Service effective: Our sales people promise to reply your enquiry within 12 hours.Contact whatsapp 86 180 3827 3926