Last Updated on 12/14/2025 by dtent.net

The global tent manufacturing landscape is evolving at an unprecedented pace. As a tent manufacturer, understanding emerging technologies, sustainability mandates, and shifting consumer expectations isn’t optional—it’s existential. This analysis unpacks critical strategies for tent manufacturers to lead in the $4.5B outdoor shelter market.

1. Sustainable Manufacturing: The Imperative for Tent Manufacturers

Reduce footprints beyond tent footprints.

A. Material Innovation

- Biodegradable Fabrics: Leading tent manufacturers now test mycelium composites (decomposes in 90 days) and algae-based coatings.

- Recycled Content: Top performers utilize 40–100% recycled PET (e.g., Patagonia’s NetPlus™ from fishing nets).

- Impact: TentCraft reduced CO₂/kg by 33% switching to recycled fabrics.

B. Circular Production Models

- Take-Back Programs: Vaude and Hilleberg reclaim used tents for recycling, offering 15% discounts on new purchases.

- Waterless Dyeing: Big Agnes adopted AirDye® tech, saving 7M liters annually.

Actionable Insight: Partner with material scientists to develop proprietary eco-fabrics.

2. Smart Technology Integration for Tent Manufacturers

Transforming shelters into connected ecosystems.

A. IoT-Enabled Tents

- Solar Integration: Tent manufacturers embed thin-film PV panels (e.g., PowerFilm Solar) into canopies for off-grid power.

- Climate Control: The North Face’s sensor-driven vents auto-adjust airflow based on humidity.

B. Safety Enhancements

- Real-Time Hazard Alerts: MSR Access Pro tents sync with weather APIs to warn users of storms via app.

- Structural Health Monitoring: Strain gauges in poles alert users of impending failures.

Case Study: Dometic’s app-controlled tent systems saw 200% ROI in 18 months.

3. Advanced Material Science: Competitive Edge for Tent Manufacturers

Where nanotechnology meets nature.

| Material | Innovation | Pioneer Tent Manufacturer |

|---|---|---|

| Dyneema® CF | 15x stronger than steel by weight | Zpacks |

| Graphene-Coated | 30% better thermal retention | Hilleberg |

| Self-Healing PU | Microcapsules repair punctures | Nemo Equipment |

Manufacturing Tip: Partner with aerospace labs for composite R&D.

4. Market Diversification Strategies for Tent Manufacturers

Beyond camping: Where revenue multiplies.

A. Glamping & Hospitality

- Luxury safari tents with HVAC and hardwood floors command 200–200–500/night (e.g., Collective Retreats collaborations).

- Opportunity: Tent manufacturers can co-develop turnkey glamping suites with resorts.

B. Disaster Response Solutions

- Rapid-deploy tents (<5-min pitch) with anti-bacterial linings (e.g., Vango Force 10 used by Red Cross).

- Growth: UN procurement of emergency tents rose 22% YoY (2023).

C. Urban Infrastructure

- Pop-up coworking tents with solar/Wi-Fi (e.g., UNStudio’s urban prototypes).

5. Consumer-Centric Design: How Tent Manufacturers Win Loyalty

Data-driven product evolution.

A. Hyper-Personalization

- Modular Tents: Nemo Dragonfly’s interchangeable panels let users convert 3-season to winter shelters.

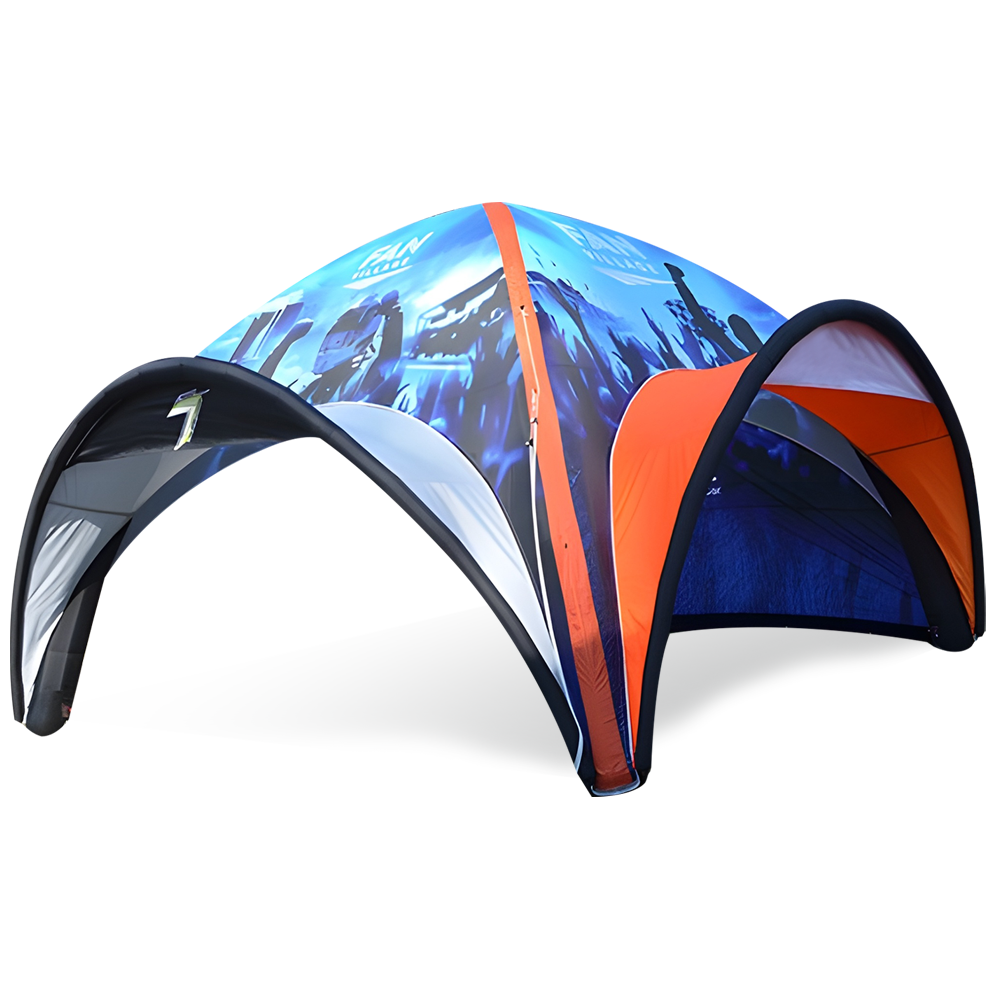

- Custom Printing: TentCraft offers full-color digital printing for brand-activation tents.

B. Ultralight Revolution

- Demand for sub-2lb solo tents surged 60% post-pandemic (Outdoor Industry Assoc.).

- Solution: Tent manufacturers adopt 3D-knitted seamless construction (e.g., Adidas Primeknit tech).

6. Manufacturing 4.0: Automation for Tent Manufacturers

Precision, speed, scalability.

A. Robotic Sewing Cells

- Hilleberg’s robotic arms achieve 0.1mm seam accuracy, cutting labor costs by 20%.

B. AI-Driven Design

- Generative algorithms (Autodesk) optimize tent geometry for wind loads, reducing material use by 18%.

C. Digital Twins

- Simulate tent performance in blizzards/monsoons pre-production.

ROI Note: Early adopters report 30% faster time-to-market.

7. Regulatory Navigation Guide for Tent Manufacturers

Turning compliance into advantage.

A. PFAS Bans (EU/US 2025–2027)

- Alternatives: Silicone/wax blends (Fjällräven) and bio-repellents (Nikwax Hydrophobic) now achieve 20,000mm waterproof ratings.

B. Tariff Mitigation

- Reshoring: 41% of tent manufacturers shifted production to Vietnam/Mexico to bypass US-China tariffs (McKinsey).

8. Future-Proofing Your Tent Manufacturing Business

2025–2030 Outlook

- Solar-Dominant Tents: 70% will integrate energy harvesting (Lux Research).

- AI Co-Design: Apps will generate custom tent blueprints based on user biomechanics.

- Carbon-Positive Materials: Algae-grown fabrics that sequester CO₂ enter mass production.

innovation For tent manufacturers

For tent manufacturers, innovation is no longer about incremental upgrades—it’s about redefining shelter itself. By mastering sustainable materials, smart technologies, and agile manufacturing, your company can dominate niches from emergency response to luxury ecotourism.

At Dtent, we engineer possibilities. Our cutting-edge facilities and R&D partnerships empower tent manufacturers to:

- Launch market-specific tent systems in <90 days

- Achieve 100% recyclable product lines

- Slash energy use by 40% via solar-powered production

Are you a Trading Company or Manufacturer?

We are a manufacturer specialized in Folding tents, Outdoor umbrellas, Beach flags, Advertising Banners

Can you do design for my ideas or drawing?

Yes, we have experienced designers and our own molding factory. According to your requirements, we can design or open mold which has a competitive price.

How long does sample take?

Sample will be ready within 5-7 days, depends on your printing and material requirements.

What is your advantage?

Cost effective; with low price; Time effective: we promise to make the mass delivery within 30 days Service effective: Our sales people promise to reply your enquiry within 12 hours.Contact whatsapp 86 180 3827 3926