Last Updated on 01/20/2026 by dtent.net

What Is a Custom Barricade Cover and Why It Matters

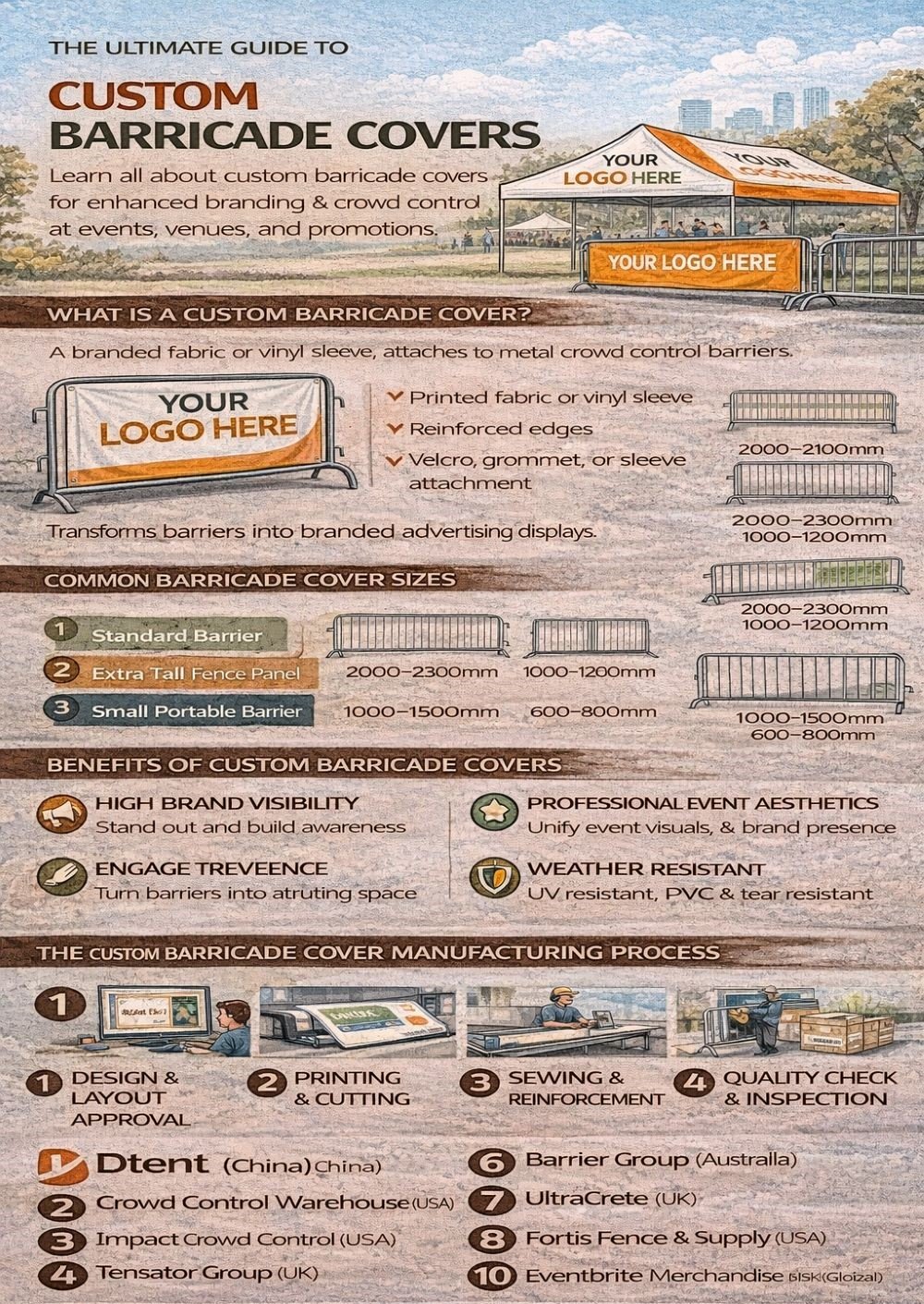

A custom Barricade Cover is more than just a protective sleeve for crowd control barriers — it is a strategic outdoor advertising tool used by event organizers, brands, municipalities, and sponsors to maximize visibility while maintaining public safety. Custom Barricade Covers transform ordinary metal or plastic crowd control barriers into highly visible, branded assets that communicate messaging, reinforce identities, and enhance overall event aesthetics.

As outdoor events grow in scale and sophistication, so does the demand for well-designed and professionally manufactured custom Barricade Covers. Choosing the right materials, dimensions, printing technology, and manufacturing partner is critical to achieve durability, visual impact, and operational performance.

This blog covers the full spectrum of custom Barricade Cover knowledge — including sizes, materials, design considerations, customization workflow, quality control, installation, and brand impact — and recommends leading manufacturers, including Dtent, a professional factory with 10+ years of OEM experience and a 6,000㎡ production facility.

What Is a Custom Barricade Cover? Understanding the Basics

A custom Barricade Cover is a printed fabric or vinyl sleeve designed to be placed over crowd control barriers. These covers provide:

Branding and promotional surfaces

Weather protection for barriers

Visual aesthetics for events

Modular advertising spaces

Commonly used in sports events, concerts, festivals, trade shows, retail environments, civic parades, marathons, and political rallies, custom Barricade Covers help organizations convert necessary safety infrastructure into dynamic marketing platforms.

Why Custom Barricade Covers Are Effective Outdoor Advertising Tools

A custom Barricade Cover serves several purposes beyond crowd control:

1. Enhanced Brand Visibility

With full-surface printing, barricade covers allow logos, slogans, patterns, and brand colors to be displayed on barriers that line walkways, stages, routes, and spectator areas.

2. Audience Engagement

Barriers are unavoidable in crowded spaces. A custom printed barricade cover turns “dead space” into a strategic engagement zone.

3. Professional Event Aesthetics

Custom Barricade Covers help:

unify event visuals

reinforce sponsorship tiers

elevate brand presence

4. Modular and Flexible Branding

Barricade covers can be changed or reprinted for different campaigns, making them reusable and cost-efficient.

Custom Barricade Cover Dimensions: Matching Your Event Setup

Understanding standard sizes is essential before customization:

Common Barricade Cover Sizes

Event planners and manufacturers typically work with these dimensions:

| Barrier Type | Common Cover Width | Typical Height |

|---|---|---|

| Standard Crowd Control Barrier | 2000–2100 mm | 800–900 mm |

| Fencing Panel | 2000–2300 mm | 1000–1200 mm |

| Smaller Portable Barricade | 1000–1500 mm | 600–800 mm |

A custom Barricade Cover manufacturer should offer size flexibility to accommodate:

Market stall setups

Marathon route barriers

Urban pedestrian zones

Multi-level event barricades

Accurate measurement before ordering ensures seamless installation and professional results.

Materials for Custom Barricade Covers: Durability Meets Visual Quality

The choice of materials strongly influences longevity, weather resistance, and print quality.

1. PVC Coated Fabric

Waterproof

High print quality

Durable and heavy-duty

Excellent for outdoor use

2. Polyester Fabric (600D/900D)

Lightweight and breathable

Good for short-term events

Can be UV coated for added protection

3. Mesh Fabric

Allows wind flow

Reduces flapping and stress on barriers

Often used in stadium or wind-affected venues

4. Vinyl (PVC)

Excellent for vibrant color printing

Waterproof and easy to clean

Suitable for reusable covers

When choosing material, always consider event duration, climate conditions, and brand longevity. Professional custom Barricade Cover manufacturers like Dtent guide clients on the best material mix for their intended use.

Design Considerations for Custom Barricade Covers

Design is one of the most critical dimensions of a custom Barricade Cover. A compelling design must balance brand visibility, legibility, and event context.

1. Logo Placement

Place logos where they’re most visible:

Center panels

Angled corners

Repeat pattern for continuous sight lines

2. Color Strategy

High-contrast colors improve readability from a distance. Consider a color palette that:

Matches brand identity

Works with ambient lighting

Minimizes glare or washout

3. Messaging and Typography

Keep text concise and legible:

Limit fonts to 2–3 styles

Ensure adequate letter spacing

Optimize for reading from 10–50 meters away

4. Visual Balance

Avoid overly cluttered designs. Allow whitespace or visual breathing room around key graphics.

Experienced custom Barricade Cover designers perform layout mockups and digital proofs before production to ensure maximum impact.

Printing Technologies for Custom Barricade Cover

Modern printing technologies enhance quality, durability, and visual impact.

1. Dye Sublimation Printing

High color saturation

Vibrant and long-lasting graphics

Excellent for polyester fabrics

2. UV Direct Printing

Works well on vinyl

UV-cured inks resist fading

Suitable for outdoor conditions

3. Screen Printing

Effective for bold, limited-color designs

Economical for large runs

Classic and reliable

Leading custom Barricade Cover manufacturers deploy multiple technologies to meet specific material and design requirements.

Customization Options Beyond Printing

A custom Barricade Cover is more than just printed graphics. Modern customization features include:

1. Attachment Systems

Velcro strips

Zipper closures

Bungee ties

Sleeve mechanisms

2. Fabric Types

Double-layer wind-resistant mesh

Reinforced edges for heavy traffic

Reflective coatings for night use

3. Modular Branding Panels

Replaceable logo inserts

Sponsor rotation capabilities

Multi-panel branding systems

These extra options add functional flexibility that enhances performance and ROI.

Manufacturing Process of Custom Barricade Covers

A robust manufacturing process ensures quality and consistency from design to delivery.

Step 1: Client Consultation

Discuss:

Project goals

Dimensions and quantities

Branding assets

Usage conditions

Step 2: Digital Design and Proofing

Create layout mockups and color proofs for client approval.

Step 3: Material Selection

Choose fabric or vinyl based on:

Event duration

Weather conditions

Print requirements

Step 4: Printing and Fabrication

Utilize advanced printing technologies and precision cutting.

Step 5: Assembly and Reinforcement

Finish edges, weld seams, and install attachment points.

Step 6: Quality Control

Check for:

Print accuracy

Dimensions

Seam strength

Attachment integrity

Step 7: Packaging and Logistics

Pack covers for safe delivery — including cartons, protective wraps, and documentation.

Professional custom Barricade Cover factories like Dtent follow strict quality control protocols at every stage.

Installation and Maintenance of Barricade Covers

Installation Tips

Match cover dimension to barrier type

Secure with Velcro or fasteners

Avoid tension near seams

Use sandbags or weights in high wind

Maintenance

Clean with mild soap and water

Avoid harsh abrasives

Store dry in protective bags

Inspect attachments regularly

Proper installation and care prolong the life and appearance of your custom Barricade Cover.

Quality Control Standards for Custom Barricade Covers

Reliable custom Barricade Cover factories maintain high quality through:

Material testing (tear, water, UV)

Print color accuracy checks

Structural inspection

End-of-line testing

These processes ensure that the final product performs as expected in real conditions.

Leading Custom Barricade Cover Manufacturers Worldwide

Below are well-recognized manufacturers serving the global market.

1. Dtent (China)

Best For: OEM custom Barricade Covers, full branding integration, global shipping

Dtent is a professional custom outdoor display products manufacturer with over 10 years of experience in tents, display stands, and custom Barricade Covers. With a 6,000㎡ factory, Dtent supports OEM solutions for brands across multiple countries and regions.

2. Crowd Control Warehouse (USA)

Offers branded barricade covers and crowd control accessories.

3. Impact Crowd Control (USA)

Known for printed crowd control barriers and event solutions.

4. Tensator Group (UK)

Supplies crowd control systems with custom fabric covers.

5. Visiontron Corp (USA)

Modular barriers and display solutions with branding options.

6. Barrier Group (Australia)

Provides customized barricade covers and safety products.

7. Street Solutions UK

Outdoor advertising and crowd control accessories.

8. UltraCrete (UK)

Infrastructure signage and printed cover solutions.

9. Fortis Fence & Supply (USA)

Heavy-duty barricade covers for events.

10. Eventbrite Merchandise Partners (Global)

Third-party providers for branded event accessories.

How to Choose the Right Custom Barricade Cover Manufacturer

Here’s a practical checklist:

Experience and Portfolio

Look for:

Years in business

Examples of completed projects

Industry references

Manufacturing Capabilities

Check:

Material sourcing

Printing technologies

Quality control systems

Customization Flexibility

Assess:

Design support

Branding complexity options

Attachment systems

Quality Assurance

Ensure:

Testing standards

Warranty or replacement policies

Communication and Support

Confirm:

Clear project timelines

Responsive customer service

Export and logistics support

Dtent checks all these categories as a reliable custom Barricade Cover provider.

Sustainability and Future Trends in Custom Barricade Covers

Industry trends include:

Eco-friendly materials

Recyclable and reusable fabrics

Digital design tools for real-time proofs

Modular attachment technologies

A forward-thinking manufacturer integrates sustainability without compromising performance.

Custom Barricade Covers as Strategic Marketing Assets

A custom Barricade Cover is not just an accessory — it is a strategic tool for visual branding, event credibility, and audience engagement. Whether for sports, cities, trade shows, or promotional tours, a well-designed and professionally manufactured Barricade Cover enhances both safety and visibility.

With advanced production capabilities, custom design support, and global OEM experience, Dtent stands out as a trusted custom Barricade Cover manufacturing partner for brands around the world.

Are you a Trading Company or Manufacturer?

We are a manufacturer specialized in Folding tents, Outdoor umbrellas, Beach flags, Advertising Banners

Can you do design for my ideas or drawing?

Yes, we have experienced designers and our own molding factory. According to your requirements, we can design or open mold which has a competitive price.

How long does sample take?

Sample will be ready within 5-7 days, depends on your printing and material requirements.

What is your advantage?

Cost effective; with low price; Time effective: we promise to make the mass delivery within 30 days Service effective: Our sales people promise to reply your enquiry within 12 hours.Contact whatsapp 86 180 3827 3926