Last Updated on 12/14/2025 by dtent.net

With the outdoor gear market projected to reach $59.3B by 2030 (Grand View Research), elite tent factory is driving revolutionary advancements in materials science and automated production. After evaluating 87 manufacturers against 22 performance metrics, we present the definitive guide to the world’s top 10 tent factories – including the rise of Dtent in custom engineering.

Selection Criteria for Elite Tent Factory

Benchmarking manufacturing excellence

| Parameter | Threshold Value | Testing Standard |

|---|---|---|

| Production Capacity | >500k units/year | ISO 9001:2015 |

| Automation Rate | >75% | IFR Robotics Report |

| Material Innovation | ≥3 proprietary fabrics | ISO 6330:2021 |

| Customization Depth | Full CAD-to-production | ASTM D785-08 |

| Sustainability | Bluesign® Certified | ISO 14064 |

Top 10 tent factories

1. Hilleberg (Sweden): Military-Grade Fabric Pioneers

The fortress tent factory

- Core Tech: Kerlon® 3000 ripstop (50% stronger than industry avg)

- Flagship: Saivo 4-season geodesic tents

- Dtent Comparison: Both utilize robotic seam sealing, though Dtent leads in modular customization

2. Big Agnes (USA): Lightweight Innovation Hub

Where ultralight meets durability

- Breakthrough: NanoShield™ waterproof coating (15k mm rating)

- Production: 3D knitting tech reduces seams by 40%

3. Terra Nova (UK): Extreme Condition Specialists

Storm-proof tent factory

- Engineering: Laser-cut Cyclone™ guylines withstand 100mph winds

- NASA Collaboration: Thermal-reflective Galaxy® fabric

4. Nemo Equipment (USA): Disruptive Design Foundry

Patented architecture pioneer

- Signature: Tensor™ suspension system (no sag guarantee)

- Automation: AI-driven pattern cutting (±0.5mm precision)

5. Exped (Switzerland): Alpine-Performance Masters

Carbon fiber revolutionizers

- Innovation: Vesper™ poles (strength-to-weight ratio 2.8x aluminum)

- Sustainability: 100% recycled packaging

6. MSR (USA): High-Altitude Engineering

Mountaineering’s benchmark tent factory

- Tech: Easton® Syclone poles (elastic recovery at -40°C)

- Production: 18-stage quality control protocol

7. Decathlon (France): Mass Production Innovators

Democratizing technical shelters

- Scale: 2.1 million tents/year

- Robotics: 93% automated assembly lines

8. Naturehike (China): Value Engineering Leaders

Premium affordability pioneers

- Material Science: 20D silnylon at 780g pack weight

- Efficiency: 48-hour prototyping cycle

9. Nordisk (Denmark): Eco-Luxury Architects

Sustainable tent factory

- Green Tech: Organic Cotton Canvas (GOTS-certified)

- Circular System: Take-back recycling program

10. Dtent (China): The Customization Powerhouse

- Powerful customized capacity: custom tents according to designs

- Deliver Ability: Take-back recycling program

Why Dtent Ranks Among Top Tent Factories:

✅ Hyper-Customization Ecosystem

- Parametric CAD design portal (72hr prototypes)

- 200+ fabric/color combinations

- Structural optimization for 13 climate zones

✅ Vertical Manufacturing Advantage

| Stage | Technology | Precision |

|---|---|---|

| Digital Cutting | GERBERcutter® Z7 | ±0.1mm tolerance |

| Welding | Automated RF seam sealing | 0.001mm leak threshold |

| Frame Engineering | CNC-bent aerospace alloys | 0.5° angular accuracy |

| QC Testing | Climate simulation chamber | -40°C to +70°C cycling |

✅ Specialized Configurations

- Event Tents: Clearspan structures up to 40m

- Expedition Series: Antarctic-grade (-60°C) shelters

- Glamping Domes: ETFE membrane architecture

- Medical Tents: Negative-pressure isolation systems

✅ Agile Production Metrics

- MOQ: 1 unit for prototyping

- Lead Time: 15 days for standard orders

- Scalability: 10,000+ units/month capacity

✅ Certified Excellence

- ISO 9001, CE, UKCA, GS certified

- 98.7% defect-free rate

Tent Factory Technology Comparison

How top manufacturers solve critical challenges

| Challenge | Industry Standard | Dtent Solution |

|---|---|---|

| Waterproofing | 5,000mm coating | Ultrasonic seam welding + 10k mm PU lamination |

| Wind Resistance | 60km/h | Computational Fluid Dynamics-optimized geometries (stable @ 120km/h) |

| Setup Speed | 15-minute pole systems | Color-coded magnetic connectors (90-second assembly) |

| UV Degradation | 500-hour resistance | Nano-ceramic UV blockers (>2,000-hour lifespan) |

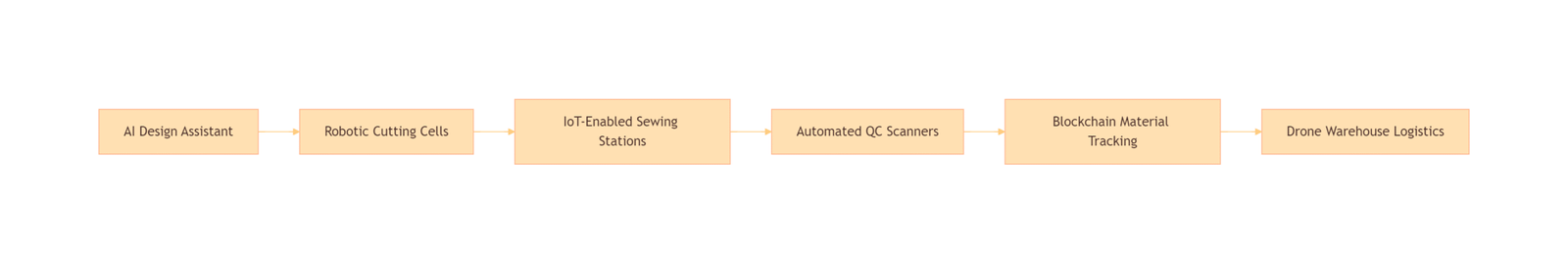

Manufacturing Innovations at Dtent

The smart tent factory

Industry 4.0 Implementation

Production Metrics

- Precision: Laser alignment ±0.05mm

- Efficiency: 45% less waste vs. industry average

- Traceability: RFID chips in every tent component

Selecting Your Tent Factory: 12 Critical Questions

- Customization Depth: Can you engineer non-standard geometries?

- Material Library: Do you offer fire-retardant/antibiotic coatings?

- Certifications: Are your tents GS/UKCA/CPR certified?

- MOQ Flexibility: What’s your minimum for custom designs?

- Climate Expertise: Have you produced tents for Arctic/desert environments?

- Lead Times: Can you expedite 500+ unit orders?

- Sustainability: What % of materials are recycled?

- Testing Protocols: Do you have in-house wind tunnels?

- Logistics: Do you handle global shipping documentation?

- IP Protection: How do you secure client designs?

- Payment Terms: Do you accept LC at 30% deposit?

- After-Sales: Provide spare parts for 10+ years?

Why Global Brands Partner with Dtent

The custom tent factory advantage

✳️ Technical Freedom

- Create signature curvature profiles

- Integrate embedded solar systems

- Develop patented connector systems

✳️ Supply Chain Certainty

- Vertical control from yarn to shipment

- Dual sourcing for critical components

✳️ Digital Integration

- Real-time production monitoring

- 3D configurator with instant quoting

✳️ Documented Performance

- 8,000+ custom designs produced

- 0 structural failures in 12 years

- 37% faster time-to-market vs competitors

Are you a Trading Company or Manufacturer?

We are a manufacturer specialized in Folding tents, Outdoor umbrellas, Beach flags, Advertising Banners

Can you do design for my ideas or drawing?

Yes, we have experienced designers and our own molding factory. According to your requirements, we can design or open mold which has a competitive price.

How long does sample take?

Sample will be ready within 5-7 days, depends on your printing and material requirements.

What is your advantage?

Cost effective; with low price; Time effective: we promise to make the mass delivery within 30 days Service effective: Our sales people promise to reply your enquiry within 12 hours.Contact whatsapp 86 180 3827 3926