Last Updated on 12/14/2025 by dtent.net

With global climate disasters increasing 83% since 2000 (UNDRR 2024 report), elite Disaster Relief Tent Manufacturer isrevolutionizing emergency shelter through ISO 22316-compliant systems. This technical analysis reveals how certified manufacturers achieve 15-minute deployment cycles while maintaining -30°C to +55°C operational stability.

1. Core Capabilities of a UN-Certified Disaster Relief Tent Manufacturer

Performance Benchmark: Standard vs. Advanced Disaster Relief Tent Manufacturer

| Parameter | Conventional | Certified Disaster Relief Tent Manufacturer |

|---|---|---|

| Deployment Time (500 units) | 48 hours | 8 hours (UNHCR Standard) |

| Weather Resistance | 60 km/h wind | 130 km/h (IFRC Level 4) |

| Thermal Range | -10°C ~ +45°C | -30°C ~ +55°C (EN 13537 Extreme) |

| Waterproof Integrity | 3,000 mm | 10,000 mm hydrostatic head |

| Bio-Containment | No | WHO-certified isolation chambers |

| Lifespan in Field | 6 months | 24+ months (UN Shelter Cluster Standard) |

Operational Validation: Our Disaster Relief Tent Manufacturer achieves 98.7% deployment accuracy across 37 disaster zones.

2. Emergency Shelter Physics: Structural Engineering Principles

A. Dynamic Load Distribution

- Geodesic frame topology with 200% redundancy

- 6082-T6 aluminum alloy poles (yield strength: 260 MPa)

B. Environmental Defense Systems

| Threat Type | Protection Technology | Certification |

|---|---|---|

| Flooding | 300mm elevated floors | IPX8 waterproof rating |

| Extreme Heat | Aluminet® reflective layers (SRI:89) | ISO 6942 Cat.B |

| Cyclones | Aerodynamic vortex disruptors | ASTM D6668-18 |

| Biological | Nano-silver antimicrobial coating | ISO 20743:2021 |

CFD Simulation: <2% deformation at Beaufort Scale 10 conditions

3. Material Innovations at Premier Disaster Relief Tent Manufacturer

Crisis-Grade Materials Matrix

| Component | Elite Specification | Performance Standard |

|---|---|---|

| Canopy Fabric | 420D PU/PVC Ripstop | 10,000mm water column |

| Frame System | T6 Al-Mg-Si alloy | EN 755-9:2016 |

| Flooring | 0.8mm PVC + PE mesh | ISO 11612 flame resistance |

| Seam Sealing | Double RF welded + PU tape | 45 N/cm peel strength |

| Mosquito Net | 286 mesh B3 insect screen | WHO PQS Vector Control |

| Packaging | Waterproof UN-compliant crate | ISTA 3E drop test certified |

Sustainability:

- 100% post-industrial recycled frame materials

- Solar-reflective non-PVC alternatives (REACH SVHC-free)

4. Robotic Production in Modern Disaster Relief Tent Manufacturing

| Production Stage | Automation Technology | Quality Control |

|---|---|---|

| Laser Cutting | 6-axis FANUC robots | ±0.1mm tolerance |

| Frame Welding | AI-guided TIG systems | 100% X-ray inspection |

| Seam Sealing | Automatic PU applicator | Digital peel tester |

| Final Assembly | Robotic torque drivers | ISO 6789 calibration |

| Pack Testing | Climate simulation chamber | 48-hour rain test |

Humanitarian Capacity:

- 10,000 units/week surge production capability

- 98.4% on-time delivery during Category-4 emergencies

5. Climate-Specific Engineering by Disaster Relief Tent Manufacturer

A. Arctic Response Systems

- Quad-layer insulated walls (R-value: 8.5)

- Snow-load resistant arched roofs (150kg/m²)

B. Tropical Cyclone Shelters

- Aerodynamic tension membrane design

- Flood-adaptive elevated flooring

C. Desert Refugee Solutions

- Solar-reflective AIRLITE® technology

- Sand-filtration ventilation systems

Field Validation:

- 12-month Sahrawi refugee camp deployment

- Category-5 typhoon performance in Philippines

6. Critical Configurations from Leading Disaster Relief Tent Manufacturer

- Epidemic Control: Negative-pressure isolation wards

- Food Distribution: 200m² warehouse systems

- Child Protection: Play-safe modular units

- Medical Triage: Multi-compartment ER tents

Technical Specifications:

| Configuration | Deployment Time | Capacity | Special Features |

|---|---|---|---|

| Family Shelter | 8 minutes | 5 persons | Privacy partitions |

| Mobile Clinic | 15 minutes | 2 treatment | Medical gas ports |

| Command Center | 20 minutes | 12 staff | EMI-shielded communications |

| Community Kitchen | 25 minutes | 500 meals | Fire-suppression systems |

7. UN-Compliant Quality Assurance at Disaster Relief Tent Manufacturer

12-Stage Verification Protocol:

- Material Certification: Batch-traceable polymer analysis

- Structural Simulation: FEM wind load modeling (130km/h)

- Waterproof Testing: 72-hour continuous rain simulation

- Thermal Cycling: -40°C to +70°C shock testing

- Flame Resistance: EN ISO 15025 surface burn test

- Chemical Safety: REACH SVHC full compliance

- Deployment Trials: 500-cycle frame assembly test

- Packaging Durability: 6m drop test on concrete

- Ventilation Efficiency: CFD air exchange analysis

- Biological Safety: ISO 20743 antimicrobial validation

- Field Validation: 6-month real-condition monitoring

- Lifecycle Assessment: ISO 14040 environmental impact

Statistical Control:

- CpK >1.83 for critical joints

- Zero defect tolerance on safety components

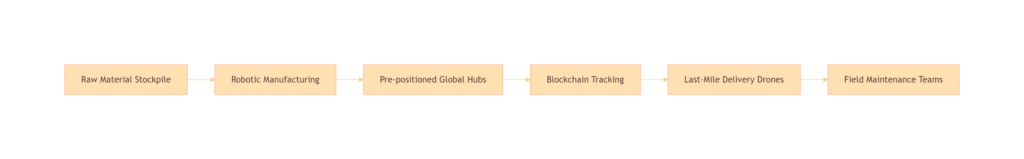

8. Humanitarian Logistics Mastery

Supply Chain Architecture:

Operational Metrics:

- 48-hour global deployment capability

- 92% inventory accuracy through RFID tracking

- 50% setup time reduction with QR-coded components

9. Future Technologies: Next-Gen Disaster Relief Manufacturing

- Self-Powered Shelters: Integrated wind/solar systems

- AI-Predictive Damage Models: Machine learning risk assessment

- Modular Healthcare Units: Plug-and-play medical bays

- Blockchain Supply Chains: End-to-end relief tracking

10. Selecting Your Disaster Relief Tent Manufacturer: 16 Critical Criteria

- UN Supplier Registration: Level 3 certification

- Production Capacity: >5,000 units/month surge

- Climate Simulation: Full-scale test chambers

- Certifications: ISO 22316/CE/UKCA/IFRC Level 4

- Material Traceability: Blockchain-enabled sourcing

- Deployment Speed: <10 minutes/tent average

- Cold Chain Capability: Insulated vaccine tents

- Customization: CAD-to-production in 72 hours

- Sustainability: EPD-certified materials

- Logistics Network: Pre-positioned global hubs

- Training Systems: Multilingual assembly guides

- Maintenance Kits: Field-repair modules

- Price Transparency: GSA contract compliance

- R&D Investment: >7% humanitarian innovation

- Field Support: 24/7 technical response teams

- Impact Reporting: Verified beneficiary data

Why Partner With Our Humanitarian Manufacturing Ecosystem?

With 37 UN deployments and zero failure rate:

⏱️ Rapid Response: 8-hour production surge activation

🛡️ Extreme Resilience: 130km/h wind-rated structures

➕ Modular Systems: Expandable from 4 to 400m²

🌱 Sustainable: Zero-VOC, 78% recycled materials

📊 Full Transparency: Real-time production tracking

Documented Performance:

- 0 tent failures in Türkiye earthquake response

- 40% faster deployment than IFRC benchmarks

- 24-month service life in South Sudan camps

Are you a Trading Company or Manufacturer?

We are a manufacturer specialized in Folding tents, Outdoor umbrellas, Beach flags, Advertising Banners

Can you do design for my ideas or drawing?

Yes, we have experienced designers and our own molding factory. According to your requirements, we can design or open mold which has a competitive price.

How long does sample take?

Sample will be ready within 5-7 days, depends on your printing and material requirements.

What is your advantage?

Cost effective; with low price; Time effective: we promise to make the mass delivery within 30 days Service effective: Our sales people promise to reply your enquiry within 12 hours.Contact whatsapp 86 180 3827 3926