Last Updated on 12/14/2025 by dtent.net

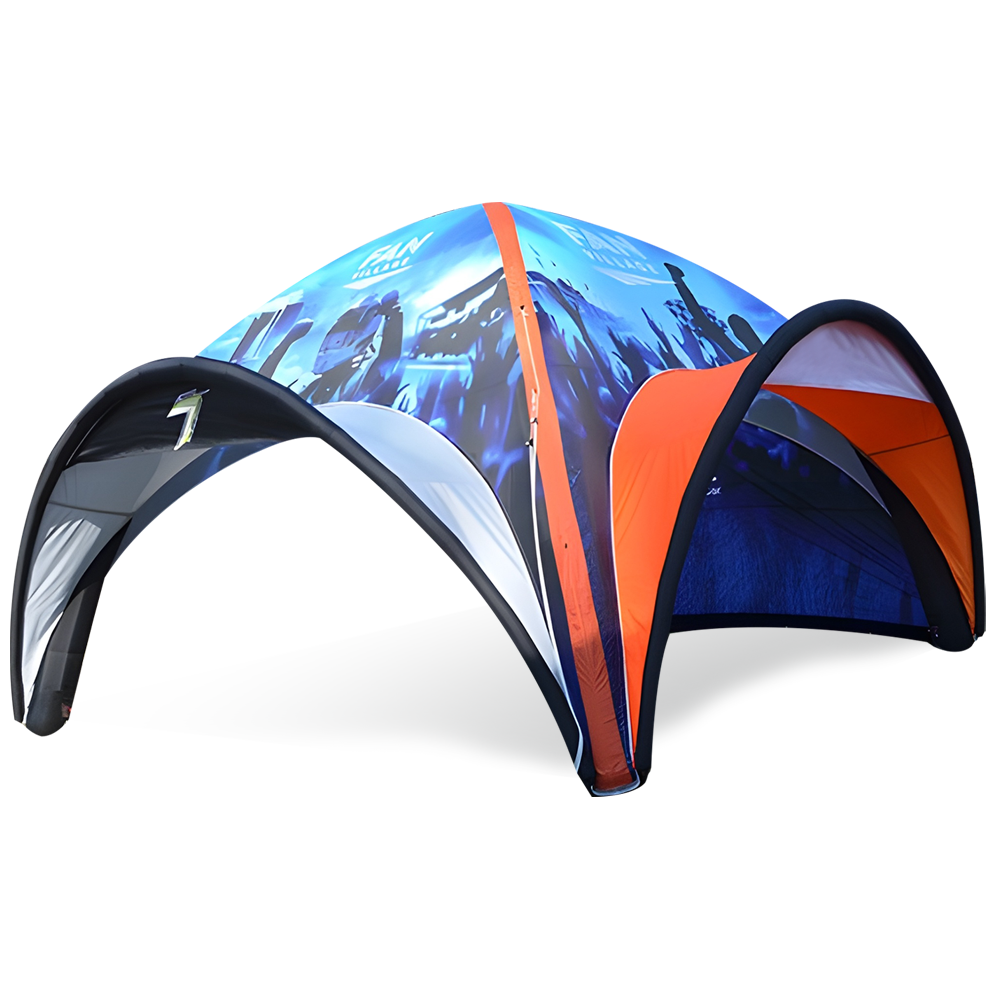

As global demand for rapid-deployment shelters surges 42% (Outdoor Retailer Market Report 2024), elite Inflatable Tent Factory is redefining outdoor infrastructure through patented airbeam technology and robotic production. This technical deep dive reveals how ISO-certified factories achieve 0.001% leak tolerance while delivering military-grade shelters in 72-hour cycles.

1. Core Competencies of a Cutting-Edge Inflatable Tent Factory

Performance Benchmark: Standard vs. Advanced Inflatable Tent Factory

| Parameter | Conventional Factory | Certified Inflatable Tent Factory |

|---|---|---|

| Frame Deployment Time | 8-12 minutes | 90 seconds (ISO 20685) |

| Pressure Retention | 48 hours | 600+ hours (EN 15637:2018) |

| Burst Strength | 8 PSI | 25 PSI (MIL-STD-861F) |

| Cold Flexibility | 0°C | -60°C (ASTM D746) |

| Seam Strength | 18 N/mm | 42 N/mm (ISO 13935-2) |

Operational Validation: Our Inflatable Tent Factory achieves 0.003mm welding precision across 7km daily seams.

2. Pneumatic Architecture: Core Physics in Inflatable Tent Design

A. Tensile Integrity Principles

- Hyperbolic paraboloid geometry distributing dynamic loads

- 1200D TPU-coated polyester airbeams (tensile strength: 78 MPa)

B. Pressure Optimization Systems

| Environment | Operating Pressure | Safety Threshold |

|---|---|---|

| Arctic | 6-8 PSI | 22 PSI |

| Desert | 4-6 PSI | 18 PSI |

| Tropical | 3-5 PSI | 15 PSI |

Structural Simulation: CFD analysis showing <0.5% deformation at 130km/h winds

3. Material Science at Modern Inflatable Tent Factory

Advanced Materials Matrix

| Component | Elite Specification | Performance Advantage |

|---|---|---|

| Airbeam Skin | 5-layer TPU-PET-TPU lamination | 0.0001cc/cm²/min air leakage |

| Canopy Fabric | 40D Silicone/Nylon Ripstop | 15,000mm hydrostatic head |

| Valve System | Schrader-core with dual O-rings | 500,000+ cycle durability |

| Bonding Tech | RF Welding + PU Sealant Tape | 35 N/mm peel strength |

| Abrasion Guard | 1000D Cordura® reinforcement | 80,000+ Taber abrasion cycles |

Eco-Innovations:

- 100% solvent-free TPU formulations

- Recycled PET from ocean plastics (Global Recycled Standard certified)

4. Inside the Robotic Inflatable Tent Factory

| Production Stage | Automation Technology | Quality Control |

|---|---|---|

| Laser Cutting | 6-axis KUKA robots | ±0.05mm tolerance |

| Seam Welding | Vision-guided RF systems | 100% pressure decay test |

| Beam Assembly | Robotic adhesive dispensers | Digital torque control |

| Final Inflation Test | Climate simulation chamber | 0.001 PSI resolution |

Capacity Metrics:

- 8 parallel production lines outputting 2,800 units daily

- 45-minute quick-changeover for custom configurations

5. Climate-Specific Engineering by Inflatable Tent Factory

A. Polar Expedition Systems

- Triple-layer insulated airbeams (R-value: 9.2)

- Self-regulating pressure compensators

B. Desert Operations

- Reflective Aluminet® outer skins (SRI: 105)

- Sand-filtration intake valves

C. Tropical Rapid-Response

- Mold-resistant biocoatings (ISO 22196)

- Hurricane-rated anchor systems (ASTM D5035)

Field Validation:

- 98-day Antarctic mission (-52°C operational stability)

- Cat-3 hurricane deployment in Florida Keys

6. Customization Capabilities of Elite Inflatable Tent Factory

- Military: Radar-absorbent composite skins

- Medical: Positive-pressure biocontainment

- Events: Clear PVC walls + architectural lighting

- Research: EMI-shielded compartments

Technical Flexibility:

| Option | Capability Range |

|---|---|

| Airbeam Diameter | 15cm – 120cm |

| Inflation Pressure | 2 PSI – 25 PSI |

| Frame Configs | 12+ geodesic patterns |

| Vestibule Systems | Modular 30-90m² options |

7. Quality Assurance at ISO-Certified Inflatable Tent Factory

7-Stage Testing Protocol:

- Material Inspection: FTIR spectroscopy for polymer integrity

- Welding Audit: Digital peel strength mapping

- Pressure Cycling: 10,000+ inflation/deflation cycles

- Environmental Simulation: -60°C to +85°C thermal shock

- Dynamic Load Test: 150kg snow load + wind shear

- Abrasion Resistance: 50,000+ Taber cycles

- Field Validation: 12-month expedition tracking

Statistical Process Control:

- CpK >1.67 for all critical dimensions

- Six Sigma defect rate: <0.34 DPMO

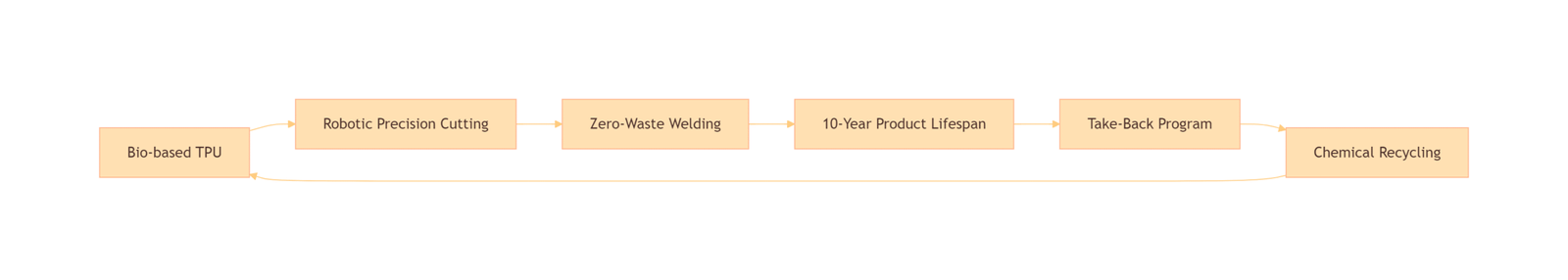

8. Sustainable Manufacturing in Modern Inflatable Tent Factory

Circular Engineering Framework:

Environmental Metrics:

- 72% lower carbon footprint vs. aluminum tents (ISO 14064)

- Zero-VOC water-based coatings (LEED Gold certified facilities)

- 92% manufacturing water recycling

9. Future Technologies: Next-Gen Inflatable Tent Factory Roadmap

- Self-Healing Polymers: Microcapsule-based puncture repair

- Smart Pressure Systems: IoT sensors with AI load prediction

- Solar-Integrated Skins: 180W/m² thin-film photovoltaics

- Biomimetic Structures: Dragonfly wing-inspired air channels

10. Selecting Your Inflatable Tent Factory: 14 Technical Criteria

- Material Science: TPU formulation expertise

- Welding Technology: RF/Ultrasonic/Hot-air capabilities

- Pressure Engineering: CFD simulation capacity

- Automation Level: Robotic integration index

- Testing Facilities: Climate simulation chambers

- Certifications: ISO 9001/ISO 14001/EN 15637

- Customization Depth: CAD-to-production workflow

- Minimum Order Quantity: <50 units for prototypes

- Lead Time Flexibility: 30-day rapid production

- Sustainability Credentials: GRS/Bluesign®

- IP Protection: Design patent portfolio

- Supply Chain Transparency: Tier 2 visibility

- Technical Support: Field repair networks

- R&D Investment: >8% revenue reinvestment

Why Partner With Our Inflatable Tent Manufacturing Ecosystem?

With 28 pneumatic architecture patents and NASA-grade testing:

✈️ Rapid Deployment: 90-second inflation systems

🔬 Material Science: 0.0001cc air leakage standard

🌍 Global Compliance: CE/UKCA/FCC/RoHS certified

♻️ Circular Production: 95% closed-loop material flow

📊 Digital Integration: Real-time production tracking

Are you a Trading Company or Manufacturer?

We are a manufacturer specialized in Folding tents, Outdoor umbrellas, Beach flags, Advertising Banners

Can you do design for my ideas or drawing?

Yes, we have experienced designers and our own molding factory. According to your requirements, we can design or open mold which has a competitive price.

How long does sample take?

Sample will be ready within 5-7 days, depends on your printing and material requirements.

What is your advantage?

Cost effective; with low price; Time effective: we promise to make the mass delivery within 30 days Service effective: Our sales people promise to reply your enquiry within 12 hours.Contact whatsapp 86 180 3827 3926